electrical discharge machining working principle

Fundamentally the electric erosion effect is understood by the breakdown of electrode. Electrical discharge machining EDM is a process of removing material by exposing it to repetitive controlled electrical discharges.

What Is Basic Difference Between A Turbine And The Pump Centrifugal Pump Diy Water Pump Pumps

An Overview of Electrical Discharge Machining EDM Electrical discharge machining EDM is a process of removing material by exposing it to reoccurring controlled electric discharge.

. The principle of electric spark erosion for metal processing must also meet the following conditions. Electrical discharge machining is a heat-based subtractive manufacturing process. The electrical discharge machining working process is based on the generation of sparks and metal removal through spark erosion.

It is also known as WEDM. Explanation of EDMAudio. EDM is a machining technique for electrically conductive materials in which the tool consists of a fast and controlled continuous series of electric arcs between an electrode and the workpiece.

The maximum depth of the workpiece is to be 90mm wire dia is to be 03mm and speed should be 25 to 150mmsec. WEDM process is based on the conventional EDM sparking phenomenon utilizing the widely accepted non-contact. When a discharge occurs between the electrodewire and the workpiece heat energy is generated on the workpiece.

Ad For Precise Machining and Remarkable Surface Finish. The discharge form should be a very short pulse discharge so that the spark heat is too fast to transfer to the non-processing area. The fundamental principle of metal removal in wire cut EDM is the same as EDM.

Wire electrical discharge machining WEDM is an advanced thermal machining process capable of accurately machining parts with complicated shapes especially for the parts that are very difficult to be machined by traditional machining processes. Electrical discharge Machining Working Principle. In Electro-Chemical Machining ECM process the metal removal is carried out by electrolysis.

Explanation about eletrical discharge machining wire cut working principle wire EDM animation and wire EDM application by machining a mouldOther interestin. Three main variants of electrical discharge machining EDM. This process generates heat which causes metal to be removed through erosion.

Due to the use of an electrical discharge this process is also. The process manipulates this erosion to create desirable cuts and shapes out of the raw materials. What is the basic principle of EDM.

Wire Electrical Discharge Machining WEDM. As the electric discharge takes place between an electrodewire and workpiece the thermal energy is generated on a. Strong easy to machine great surface finish isomolded graphite.

Ad Makino EDMs are designed for supreme reliability and industry leading precision. It employs electrical energy to remove metal from the workpiece without touching it. Electrical Discharge Machining EDM.

9 Images about Wire Electrical Discharge Machining WEDM. Parts Working Principle Wire Electrical Discharge Machining WEDM and also 1. EDM spark erosion is the same as when an electric spark strikes a piece of metal and burns a small hole into it.

Electric discharge machining also known as spark erosion electro-erosion or spark machining is a process of metal removal based on the principle of erosion of metals by an interrupted electric spark discharge between the electrode tool cathode and the work anode. It works on the thermo-electrical phenomenon. It is suitable for thermoelectric phenomena.

Process and applications of EDM. The spark discharge energy must be large to ensure local melting and gasification of the metal in an instant. It converts electrical discharge into thermal energy that melts or vaporizes excess material from a workpiece.

Our machines are designed for the highest level of accuracy reliability and productivity. How does wire electrical discharge machining work. In Electrical Discharge Machining EDM process the metal removal is carried out by melting and vaporization as there is a controlled erosion between two electrically conducting materials the tool and the workpiece.

Advances In Abrasive Based Machining And Finishing Processes Materials Forming Machining And Tribology Paperback Department Of Mechanical Engineering Study Program Paperbacks

The Operating Principle Of Liquid Vacuum Pumps And Compressors Electrical Projects Mechanical Engineering Engineering Student

Abrasive Jet Machining Definition Principle Process Working Advantages Disadvantages Applications With Pdf

Wire Electrical Discharge Machining Also Call Wedm Its Working Principle Is The Use Of Continuous Moving Thin Wire Called Cnc Cool Things To Buy Sheet Metal

Mechanical Principle 61 3q Machining Video In 2022 Diy Wood Projects Furniture Mechanical Design Metal Furniture Design

Resistance Seam Welding Rsew Seam Welding Welding Seam

Trimetal Contact Rivets Manufacturer Supplier In India R S Electro Alloy Electricity Alloy Contacts

Mist Collector Provides Cnc Mist Collector To Safeguard The Cnc Machines From Dust And Oil Which Gets Settled On The Machines Mists The Collector Manufacturing

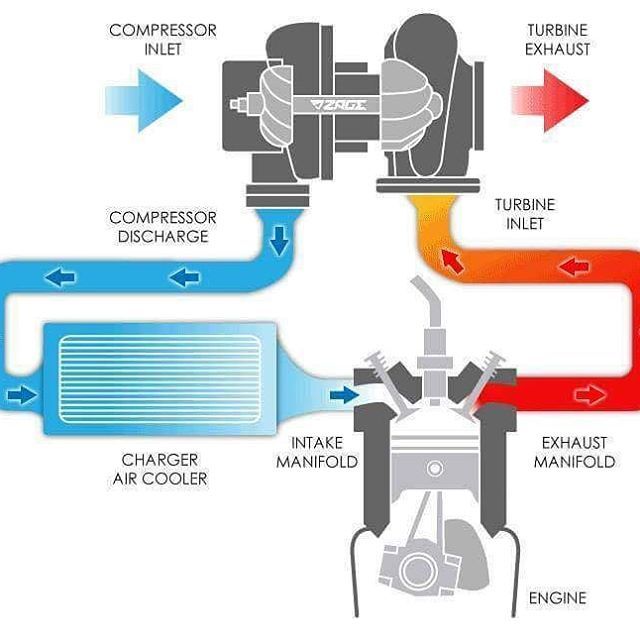

Fyi How Turbo Works Nmaa Turbo Turbocharger Kamisukaturbo Forcedinduction Engine Performance Turbocharger Automotive Engineering Automotive Mechanic

Conveyor With Chassis Clearance Forderband Freiraum Getriebe

What S The Real Isotropic Graphite News

強政科技股份有限公司jiang Jheng Technology Co Ltd Cnc Machine Tools Lathe Machine Cnc

Mechanical Principle 61 3q Machining Video In 2022 Diy Wood Projects Furniture Mechanical Design Metal Furniture Design

When Electrical Discharge Machining Is Required The Disadvantages Don T Mean A Thing Once You Realize That Edm Machining Process Drilling Machine Electricity